Sealant Packaging

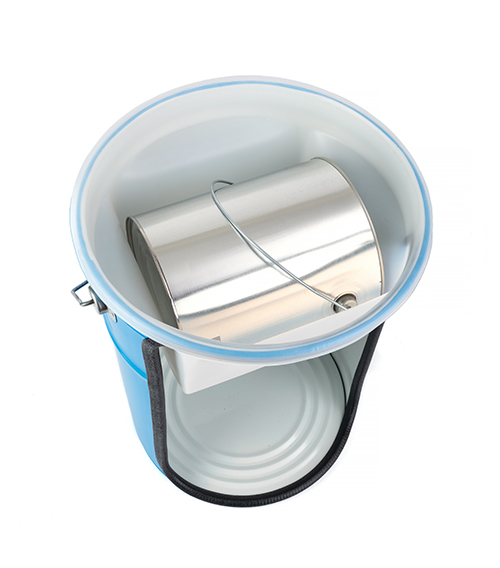

Drum & Pail Liners for Sealant Packaging

Drum liners are an essential component in the packaging, storage, and transportation of various products, including sealants in the industrial market. These liners serve multiple purposes, ensuring product quality, facilitating easy dispensing, and enhancing safety and cleanliness.

There are various other benefits of drum and pail liners for sealant packaging. For instance, they’re known for their ease of maintenance, notably when it comes to simplifying the cleaning process.

Key Benefits of Drum & Pail Liners:

- Preventing Leaks

- Ease of Cleaning

- Facilitating Dispensing

- Cost-Effectiveness

- Recycling and Reuse

- Variety of Materials

Drum & Pail Accessories & Complimentary Products

Our complimentary products for our drum and pail line offer innovative packaging solutions for plastic and steel drums and pails, created to enhance the overall customer experience by providing processing solutions and innovative packaging options.

IBC Liners for Sealant Packaging

IBC liner bags help keep a product safe and ensure it will remain high-quality. CDF offers a variety of IBC liners for sealant packaging, including:

- Pillow liners

- Air-Assist liners

- Form-Fit liners

- The Defender liner

Like drum and pail liners, IBC liners also help reduce the risk of a spill, which could pose an environmental hazard. All of CDF’s IBC liners are also designed to meet compliance and regulatory standards.

Bag-in-Box for Sealant Packaging

As the name implies, bag-in-box packaging consists of a flexible bag that contains the product within a corrugated outer shell, which protects the product. Thanks to its protective features, bag-in-box is a viable solution for sealant packaging, as any leakage or damage to the packaging could create an environmental and health hazard.

There are various other benefits associated with bag-in-box packaging for sealants:

- It can accommodate bag sizes up to 20 liters, making it applicable for bulk volumes of sealant.

- The corrugated box is easily recyclable, making it a more sustainable format compared to conventional formats.

- Bags can be outfitted with various fitments and closures, making for convenient product evacuation.

- Many CDF-made bags are UN-certified and approved for the transportation of both hazardous and non-hazardous materials.

Cost Effectiveness

CDF solutions lead the charge in sealant packaging innovation, prioritizing sustainability and operational efficiency to deliver cost-effective alternatives. Our dedication to streamlining the packaging process not only boosts productivity but also slashes waste, making a tangible impact on your bottom line.

Equipped with an extensive array of materials and films, each offering distinct advantages and varying thicknesses, CDF champions personalized sealant packaging solutions. This tailored approach guarantees a precise fit for your products, transcending the limitations of standard options while promoting sustainability and preserving product quality.

Environmental Impact

CDF’s range of packaging solutions, including drum and pail packaging, prioritizes eco-conscious design.

Consider sealant bag-in-box packaging: featuring a flexible bag within a recyclable corrugated shell, it reduces material usage and plastic consumption. This efficiency translates into fewer truckloads for transportation, cutting costs and emissions.

Liners provide environmental advantages by safeguarding against contamination, prolonging product lifespan, and minimizing waste. They also facilitate easier cleaning and maintenance, promoting efficiency.

Contact CDF Today

For more information about sealant packaging, fill out the form below.

Have a Question About this Product?

Our expert engineers can guide any client within any industry with a mindful solution to meet their packaging and sustainability needs, from innovative research and development to customizable designs.

With over 50 years of experience, our team of engineers collaborates with each customer to design a new packaging solution from liner selection to full systems integration to modifying existing products.